Spare Parts On Demand

In Portfolio by AZOTH3D

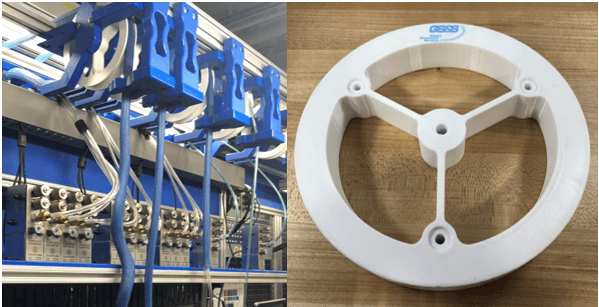

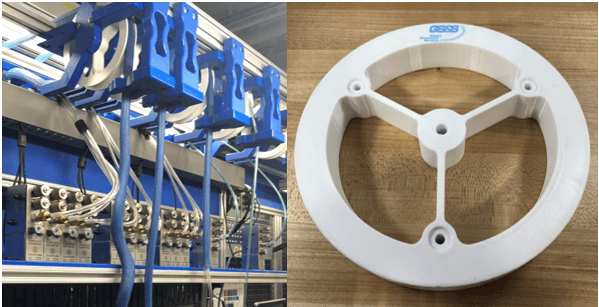

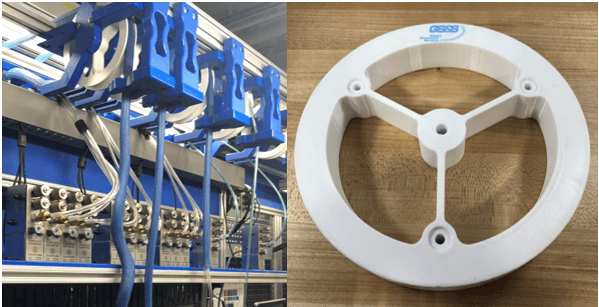

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.

There are many parts in a manufacturing plant that are not stocked in inventory, but which are needed when damaged. Azoth’s customer broke a pulley on their air spindle gage bench. The traditional supplier had a min order quantity of 20 and a 6 week lead time. Azoth was able to improve the design of the part to prevent breaking and ship the piece within 48 hrs of notification. All that was provided was the broken component for Azoth to reverse engineer.