Quality

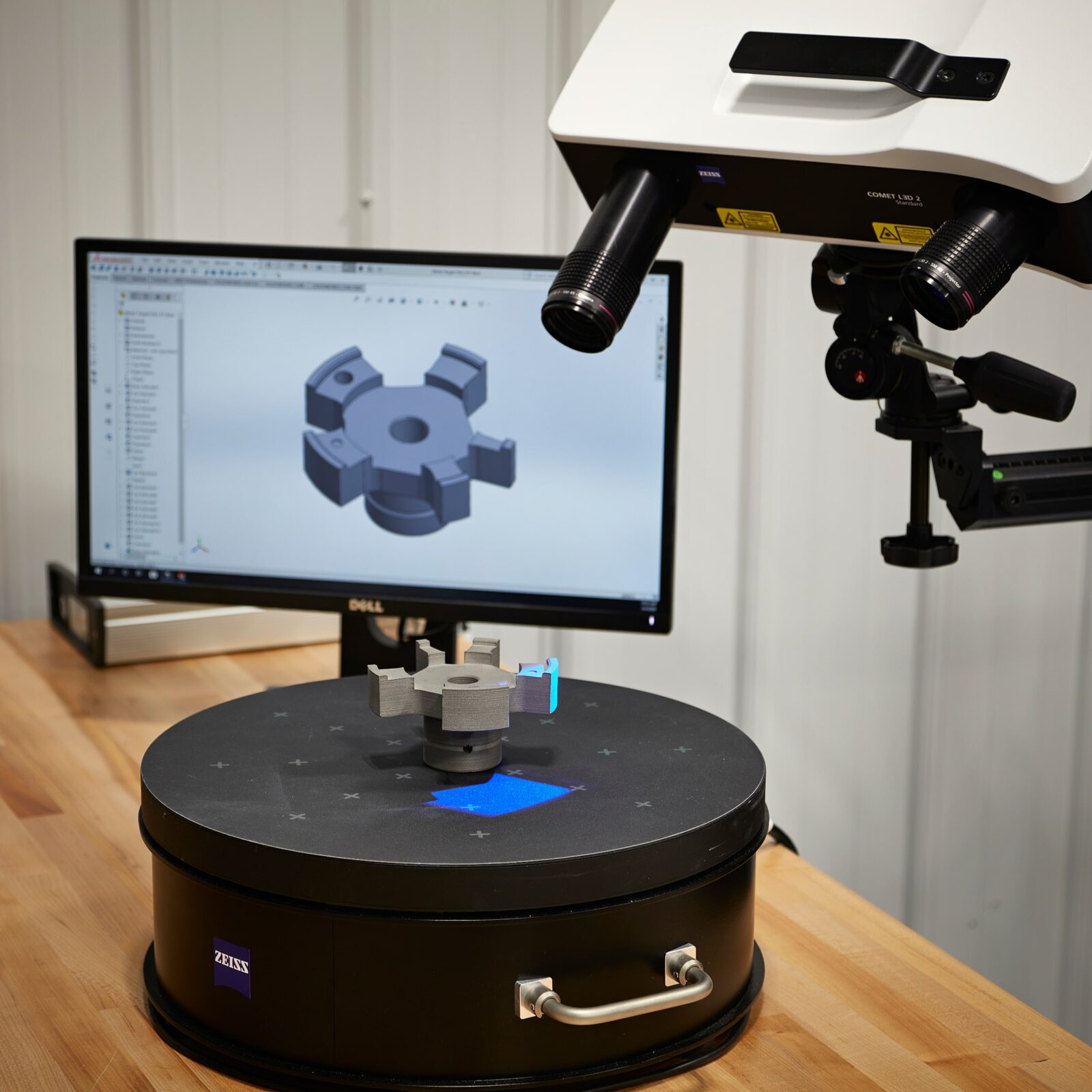

Azoth provides production capable additive (3D) manufacturing that adheres to the strictest quality standards in each of the industries it serves. Azoth is ISO-9001:2015 certified and manufactured parts are accompanied by a certificate of inspection verifying that parts have been produced based upon expectations.

Quality

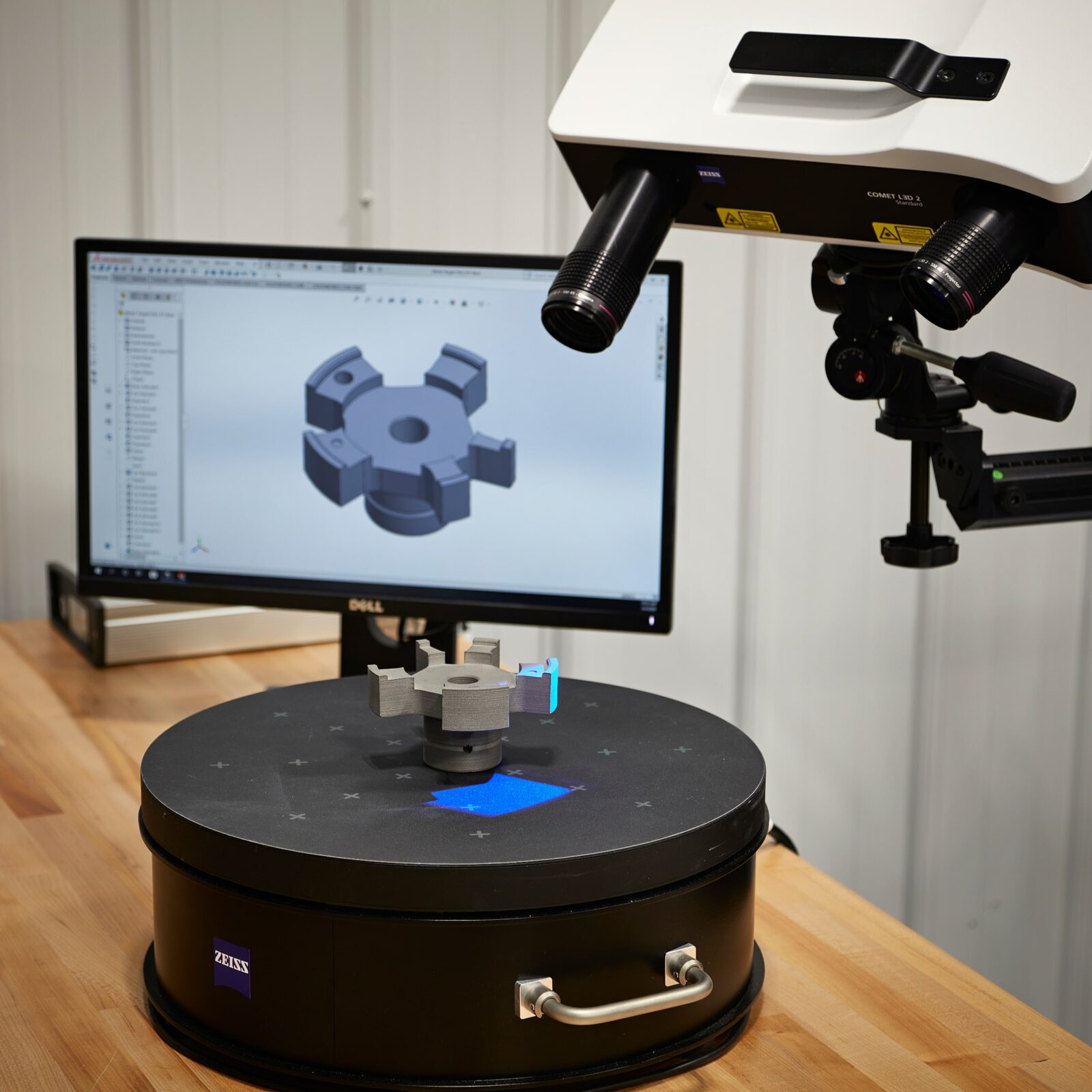

Azoth provides production capable additive (3D) manufacturing that adheres to the strictest quality standards in each of the industries it serves. Azoth is ISO-9001:2015 certified and manufactured parts are accompanied by a certificate of inspection verifying that parts have been produced based upon expectations.

Quality

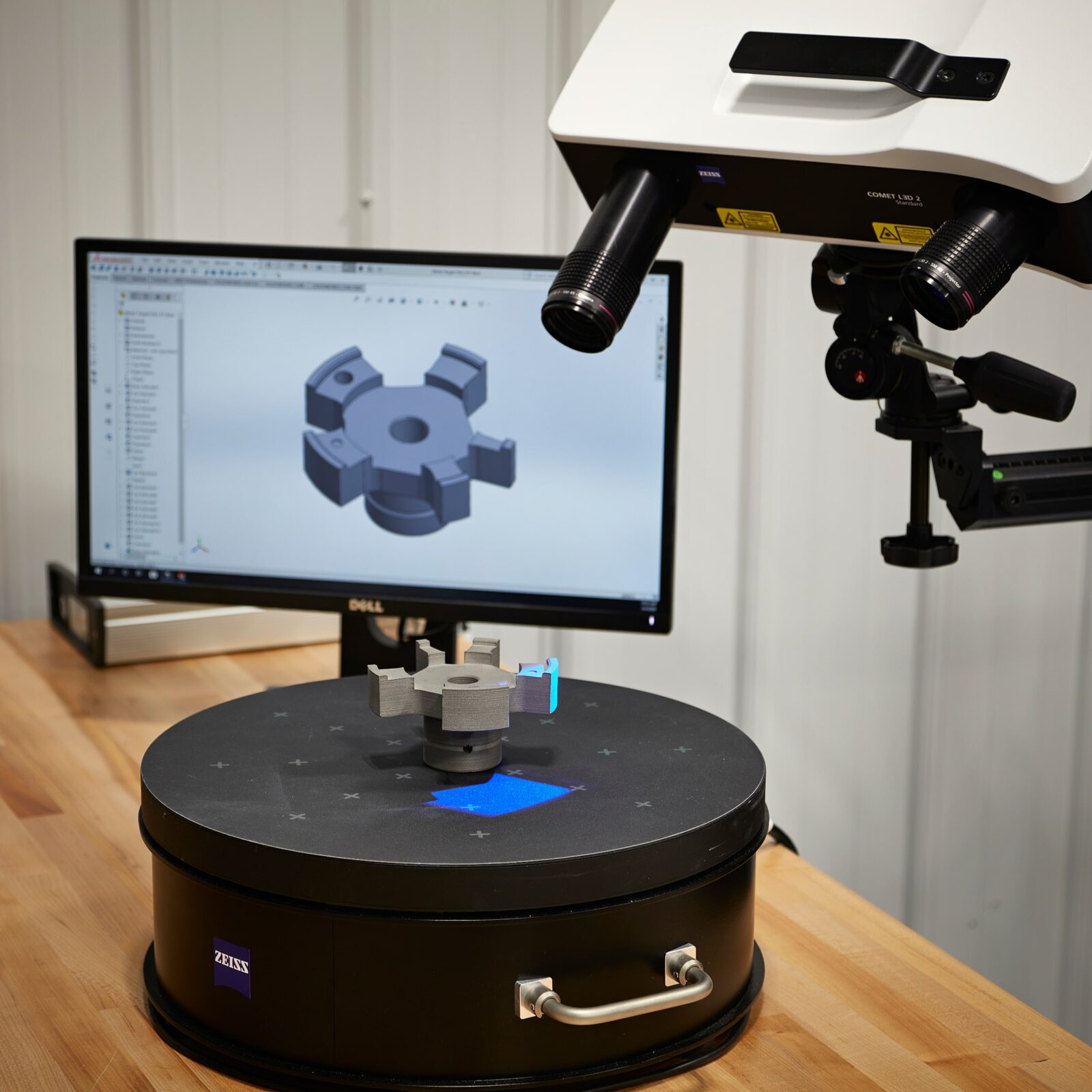

Azoth provides production capable additive (3D) manufacturing that adheres to the strictest quality standards in each of the industries it serves. Azoth is ISO-9001:2015 certified and manufactured parts are accompanied by a certificate of inspection verifying that parts have been produced based upon expectations.

Quality

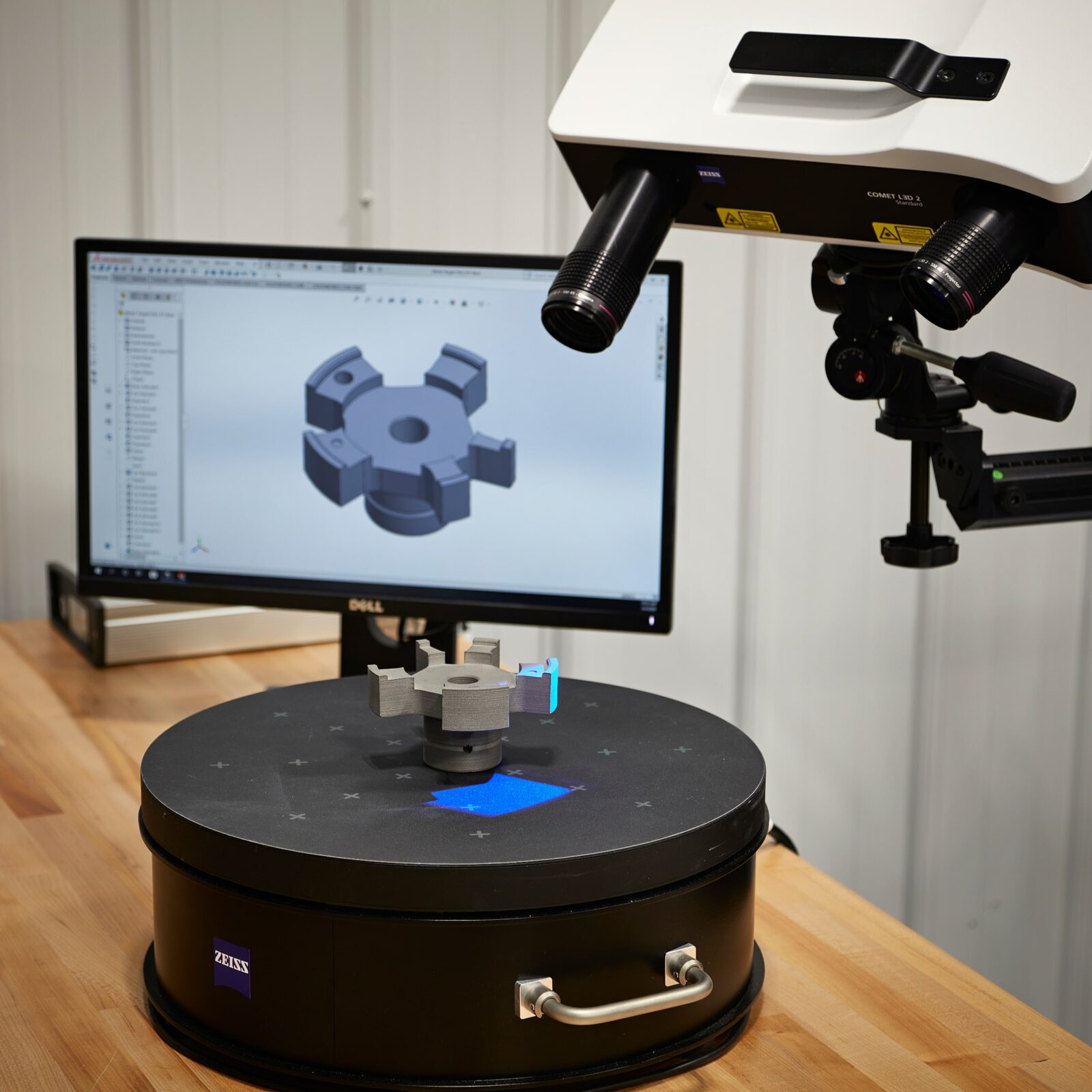

Azoth provides production capable additive (3D) manufacturing that adheres to the strictest quality standards in each of the industries it serves. Azoth is ISO-9001:2015 certified and manufactured parts are accompanied by a certificate of inspection verifying that parts have been produced based upon expectations.

Skills & Specialties

Skills & Specialties

Skills & Specialties

Skills & Specialties

Azoth is one of the few additive (3D) manufacturers familiar with the intense PPAP process desired by automotive makers and suppliers. Azoth is the first binder jet additive (3D) manufacturer to have its parts pass a rigorous PPAP process and be utilized in vehicles for General Motors.

Every part manufactured by Azoth is accompanied by a certificate of inspection verifying that your parts are produced to the agreed-upon expectations. Azoth has a full metallurgy lab, the latest in optical scanning technology, and extensive hard gaging processes to ensure your parts are to quality specifications.

Azoth operates to MPIF 35, ASTM B883, and ISO22068 material standards. Azoth adheres to ISO9001 quality standards and multiple ASTM, MPIF, and ISO testing standards.

Skills & Specialties

Skills & Specialties

Skills & Specialties

Skills & Specialties

Azoth is one of the few additive (3D) manufacturers familiar with the intense PPAP process desired by automotive makers and suppliers. Azoth is the first binder jet additive (3D) manufacturer to have its parts pass a rigorous PPAP process and be utilized in vehicles for General Motors.

Every part manufactured by Azoth is accompanied by a certificate of inspection verifying that your parts are produced to the agreed-upon expectations. Azoth has a full metallurgy lab, the latest in optical scanning technology, and extensive hard gaging processes to ensure your parts are to quality specifications.

Azoth operates to MPIF 35, ASTM B883, and ISO22068 material standards. Azoth adheres to ISO9001 quality standards and multiple ASTM, MPIF, and ISO testing standards.

Skills & Specialties

Skills & Specialties

Skills & Specialties

Skills & Specialties

Azoth is one of the few additive (3D) manufacturers familiar with the intense PPAP process desired by automotive makers and suppliers. Azoth is the first binder jet additive (3D) manufacturer to have its parts pass a rigorous PPAP process and be utilized in vehicles for General Motors.

Every part manufactured by Azoth is accompanied by a certificate of inspection verifying that your parts are produced to the agreed-upon expectations. Azoth has a full metallurgy lab, the latest in optical scanning technology, and extensive hard gaging processes to ensure your parts are to quality specifications.

Azoth operates to MPIF 35, ASTM B883, and ISO22068 material standards. Azoth adheres to ISO9001 quality standards and multiple ASTM, MPIF, and ISO testing standards.

Skills & Specialties

Skills & Specialties

Skills & Specialties

Skills & Specialties

Azoth is one of the few additive (3D) manufacturers familiar with the intense PPAP process desired by automotive makers and suppliers. Azoth is the first binder jet additive (3D) manufacturer to have its parts pass a rigorous PPAP process and be utilized in vehicles for General Motors.

Every part manufactured by Azoth is accompanied by a certificate of inspection verifying that your parts are produced to the agreed-upon expectations. Azoth has a full metallurgy lab, the latest in optical scanning technology, and extensive hard gaging processes to ensure your parts are to quality specifications.

Azoth operates to MPIF 35, ASTM B883, and ISO22068 material standards. Azoth adheres to ISO9001 quality standards and multiple ASTM, MPIF, and ISO testing standards.