MATERIALS

Azoth can utilize several different materials for Nano-Particle Jetting.LEARN MORE

SPECIFICATIONS

Azoth can work with your engineers to your exact blueprint and quality standards.

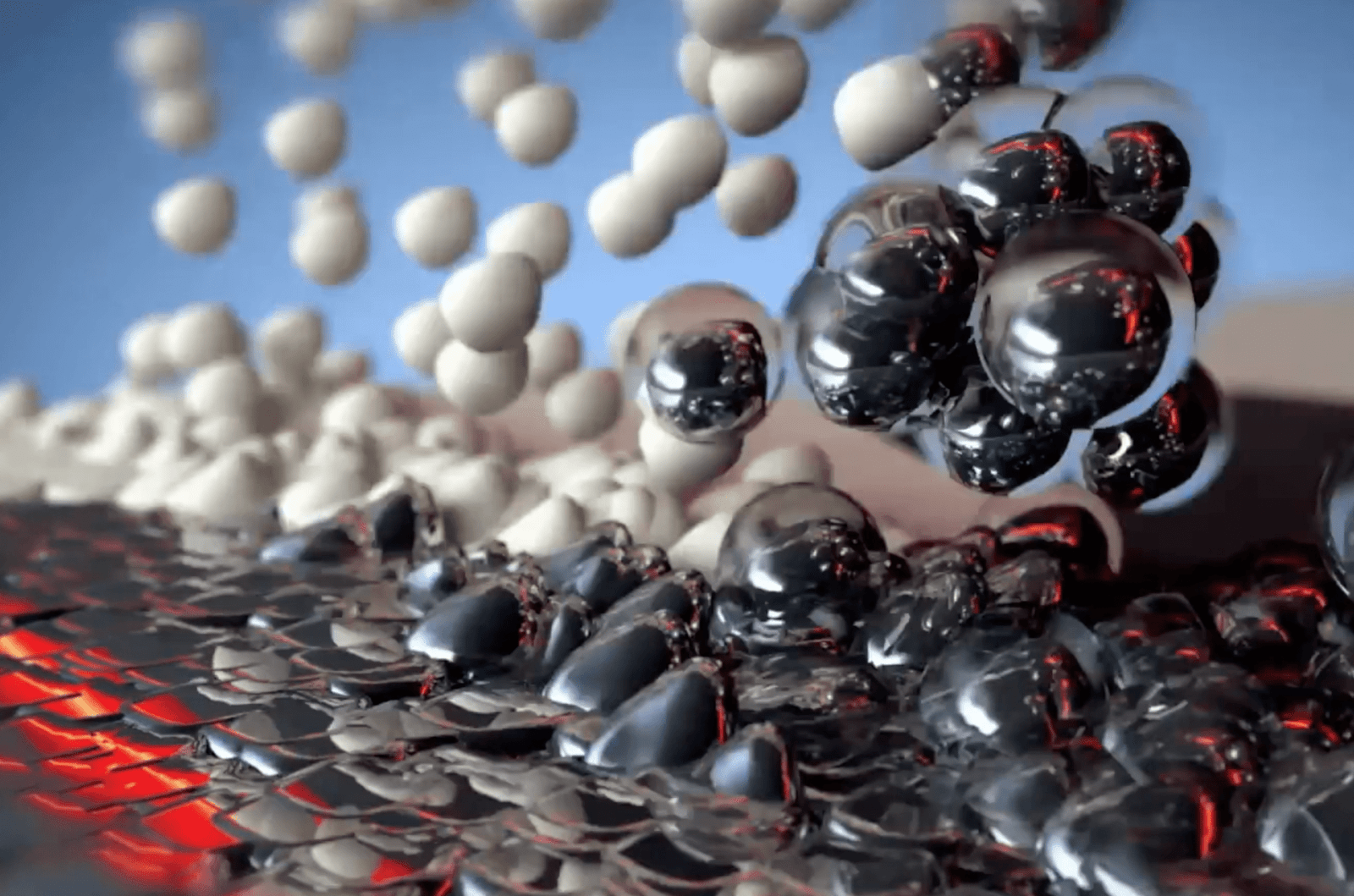

Why Nano-Particle Jetting?

NPJ allows for many small, complex parts - such as hearing aids, surgical tools, crowns, bridges, high-temperature and friction resistant parts for aerospace and automotive, and sensors for the electrical industry - to be produced at once. The NPJ process can be controlled droplet by droplet up to +- 25 microns for small parts, allowing for extremely fine detail that can’t be matched by other additive technologies.

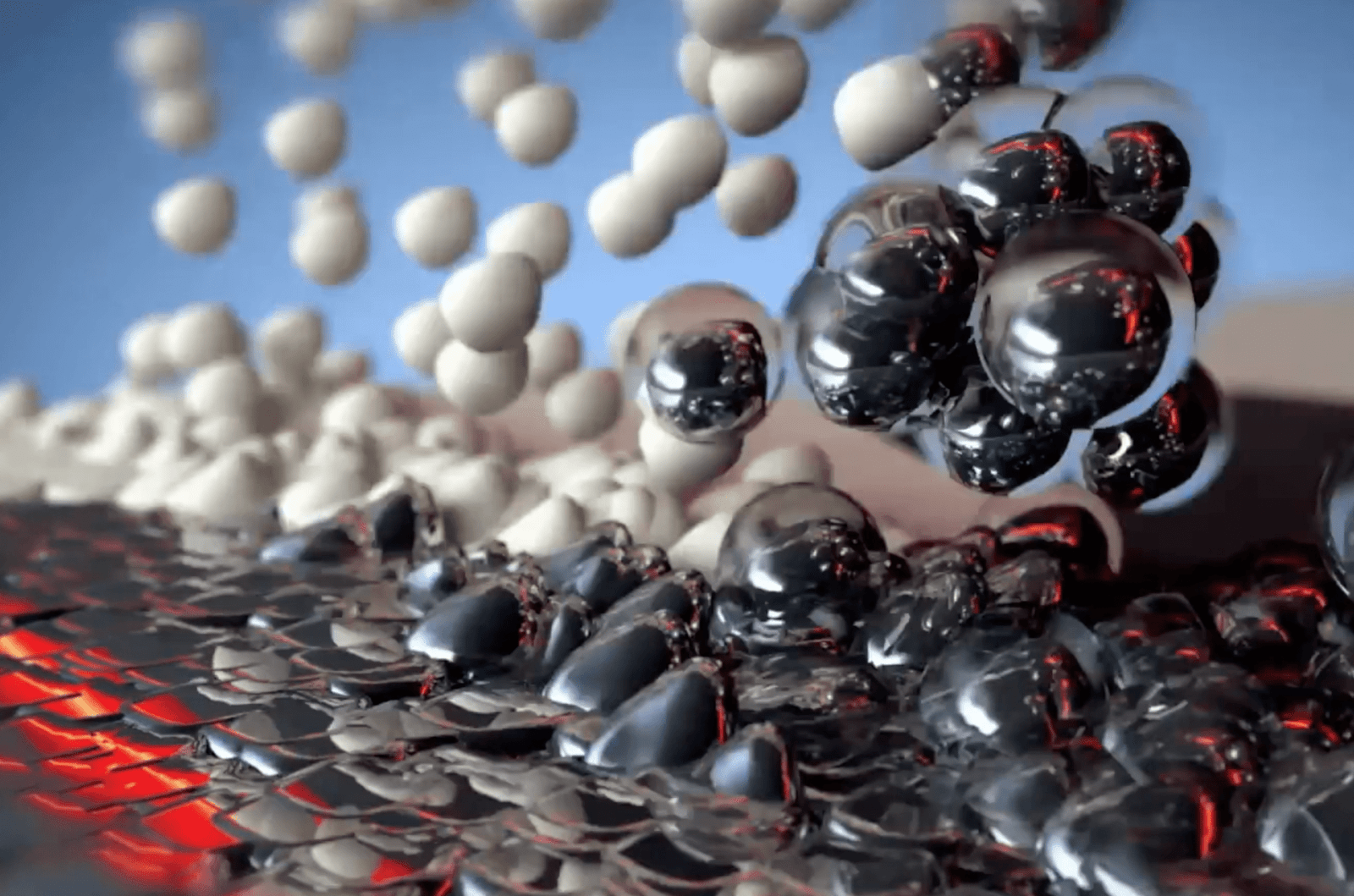

Why Nano-Particle Jetting?

NPJ allows for many small, complex parts - such as hearing aids, surgical tools, crowns, bridges, high-temperature and friction resistant parts for aerospace and automotive, and sensors for the electrical industry - to be produced at once. The NPJ process can be controlled droplet by droplet up to +- 25 microns for small parts, allowing for extremely fine detail that can’t be matched by other additive technologies.

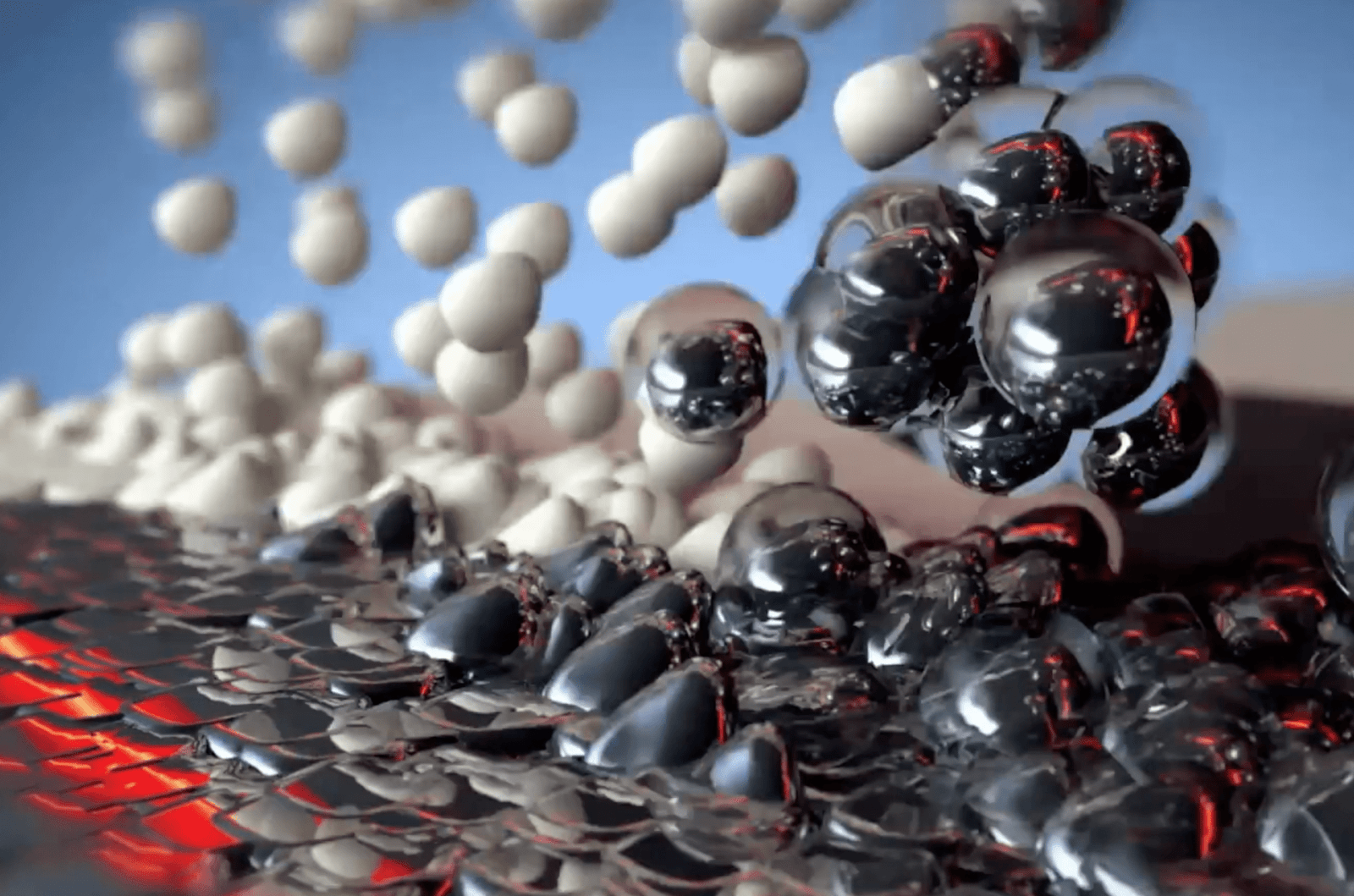

Why Nano-Particle Jetting?

NPJ allows for many small, complex parts - such as hearing aids, surgical tools, crowns, bridges, high-temperature and friction resistant parts for aerospace and automotive, and sensors for the electrical industry - to be produced at once. The NPJ process can be controlled droplet by droplet up to +- 25 microns for small parts, allowing for extremely fine detail that can’t be matched by other additive technologies.

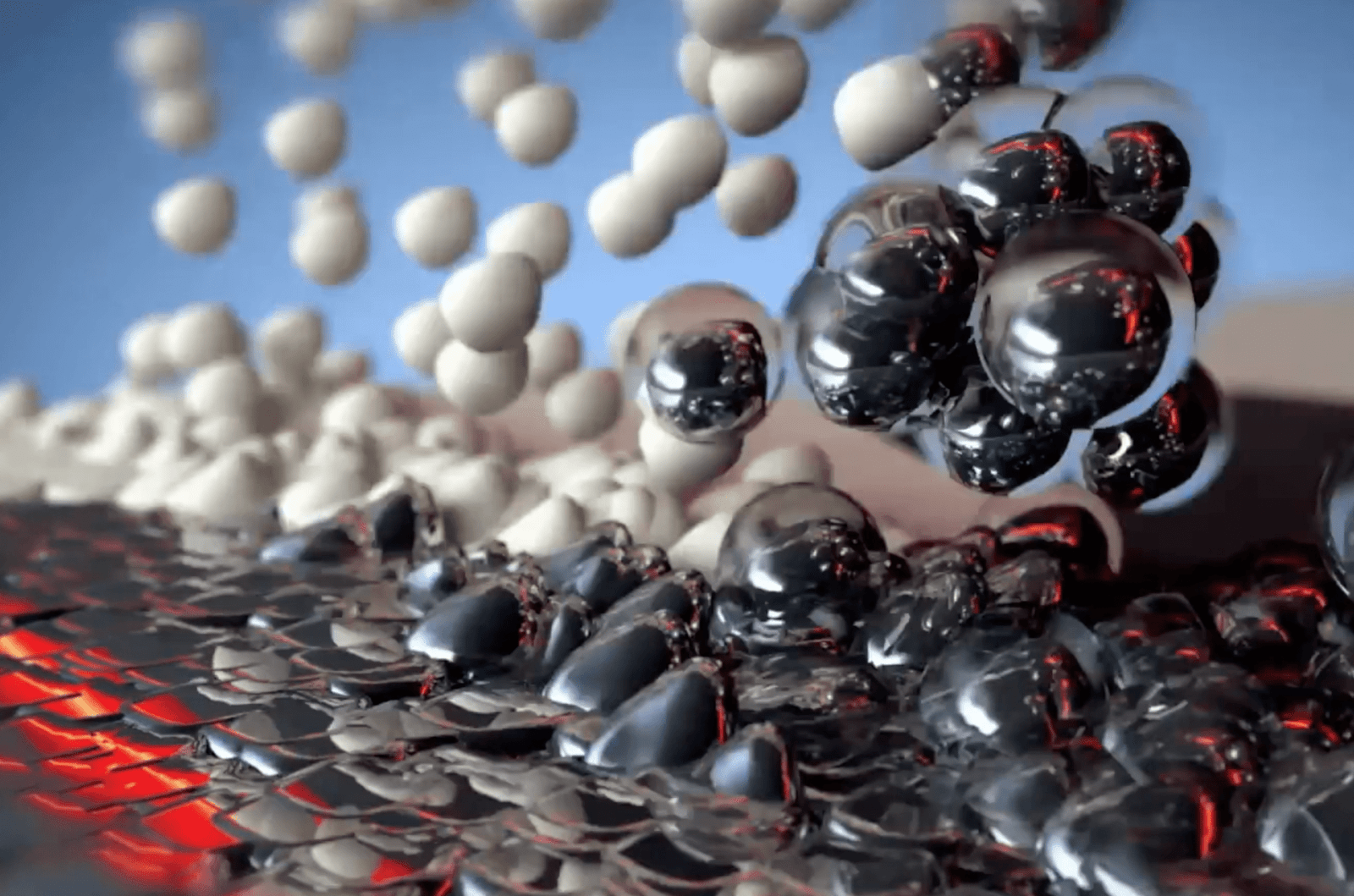

Why Nano-Particle Jetting?

NPJ allows for many small, complex parts - such as hearing aids, surgical tools, crowns, bridges, high-temperature and friction resistant parts for aerospace and automotive, and sensors for the electrical industry - to be produced at once. The NPJ process can be controlled droplet by droplet up to +- 25 microns for small parts, allowing for extremely fine detail that can’t be matched by other additive technologies.