Azoth is the first to manufacture a Metal 3D printed part using binder jetting on a General Motors production vehicle.

Azoth is seamlessly incorporated with over 15 Tier-One Automotive Suppliers and Original Equipment Manufacturers (OEMs), boasting a portfolio of over 50 distinctive components currently in serial production, each accompanied by robust levels three and four Production Part Approval Process (PPAP) documentation.

Safety Critical and Functional

Our quality assurance encompasses mechanical qualification processes that guarantee the reliability of our parts. Committed to industry-leading validation benchmarks, we proudly hold OEM certifications, signifying our dedication to meeting and exceeding the stringent requirements of the automotive industry

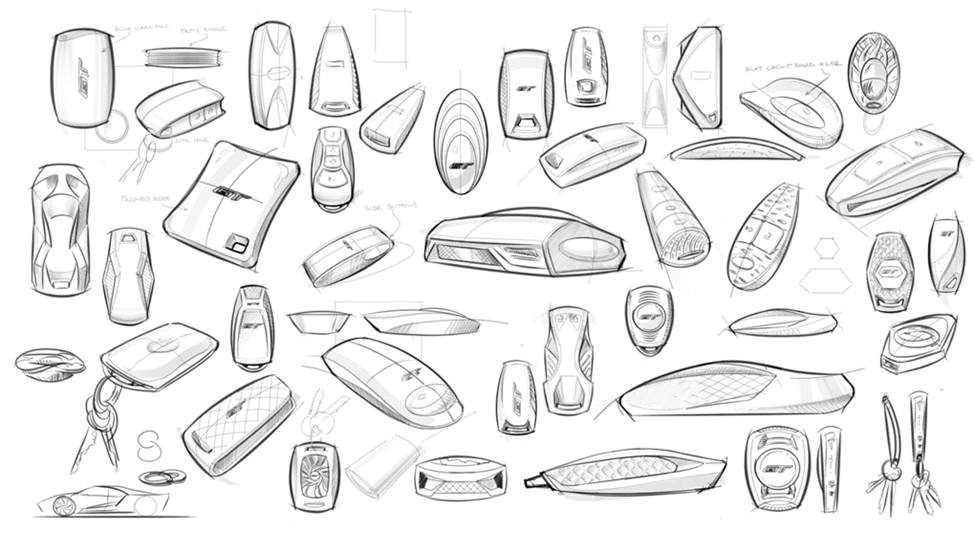

Cosmetic

Dive into a new world of refinement with our cosmetic components, where the artistry of 3D printing comes to life. We craft components with unique and intricate textures, offering a visual and tactile experience like never before.

Our skilled team meets and exceeds the industry standards with high-polish capabilities, ensuring a flawless finish that captivates the eye. Moreover, our team's expertise extends to producing parts with diverse finishes on selective surfaces, providing a bespoke touch to every design.

Setting a gold standard for visual inspections, we take pride in our OEM-approved master models, affirming our commitment to excellence in both form and function.

Align with Azoth as your premier supplier for exceptional and unparalleled parts, where our expertise in 3D printing and finishes sets a new benchmark in automotive design.

Tooling and Prototyping

In the vehicle and on the factory floor – Azoth breaks the constraints of conventional manufacturing methods to redefine tooling. With the ability to create more efficient tools faster, eliminate the long lead times and expansive inventory.

In the realm of prototyping, Azoth accelerates your time to market by enabling designers to rapidly iterate, bringing your final design to life with unprecedented speed and precision. Our metal 3D printed prototypes boast high fidelity and functionality, providing an authentic preview of your production automotive parts.

Production Part Approval Process (PPAP)

As a leading force in the industry, Azoth is your premier partner in delivering excellence to automotive. With a profound expertise in Production Part Approval Process (PPAP) and Advanced Product Quality Planning (APQP), we redefine reliability. Our professionals ensure that every product fulfills industry standards and meets your automotive needs.

For those unfamiliar with PPAP, rest assured—we will guide you through the process seamlessly. PPAP, a standardized quality assurance framework, encompasses documentation, inspection, and testing procedures. We develop PPAP packages compliant with customer requirements including, but not limited to:

- Part Submission Warrant (PSW)

- Control Plan

- PFMEA

- Appearance Approval Report, if applicable

From initial submission to final approval, we ensure reliability and compliance. Elevate your expectations; choose Azoth for a future of quality excellence.