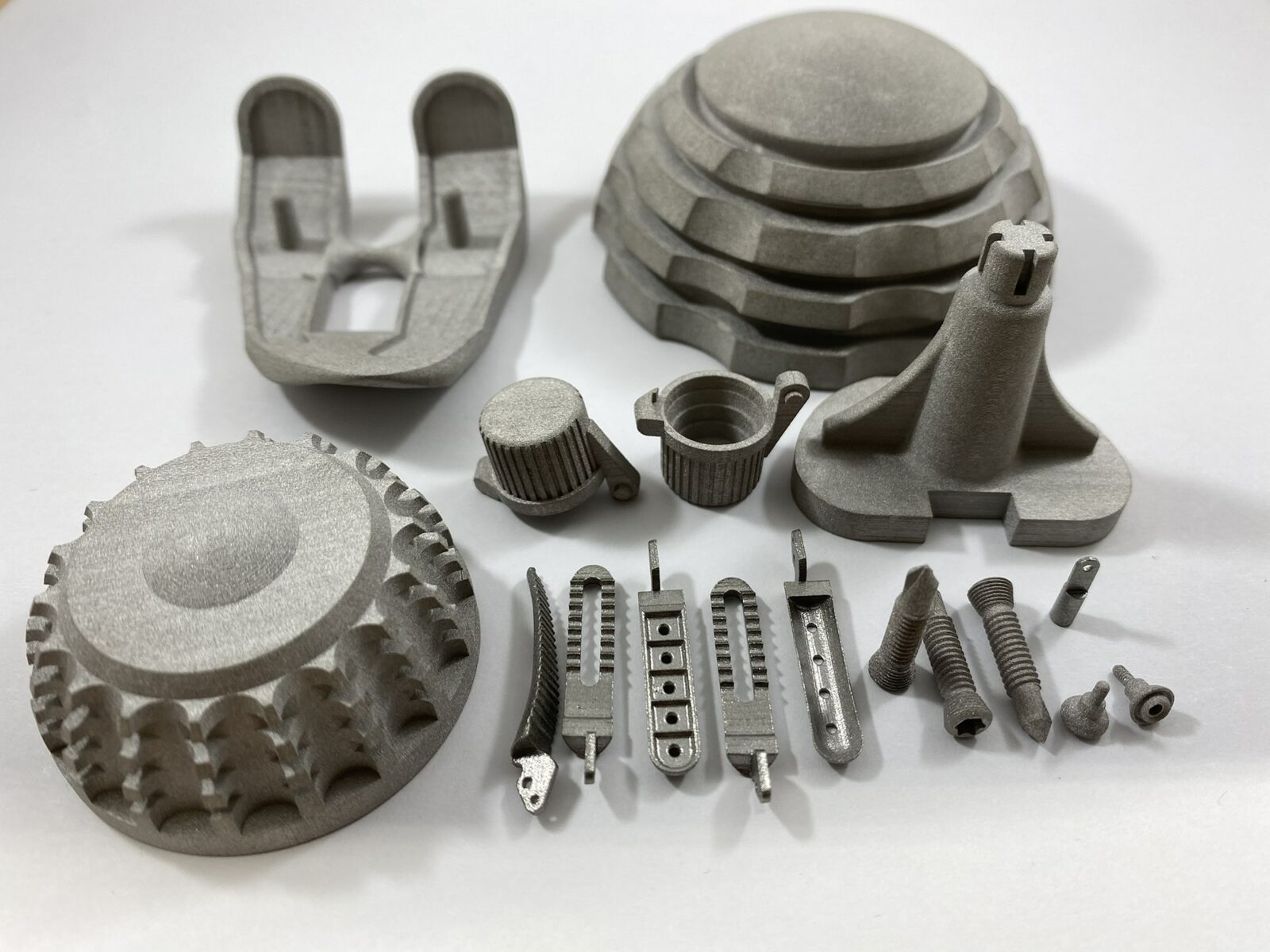

Azoth’s additive technology is a disruptive force in traditional manufacturing through its quick production lead times and TOMO® (Take One Make One). The TOMO process is designed to convert physical inventory to digital inventory eliminating supply chain disruptions, inventory obsolescence and saving its partners significant inventory costs and cash flow.

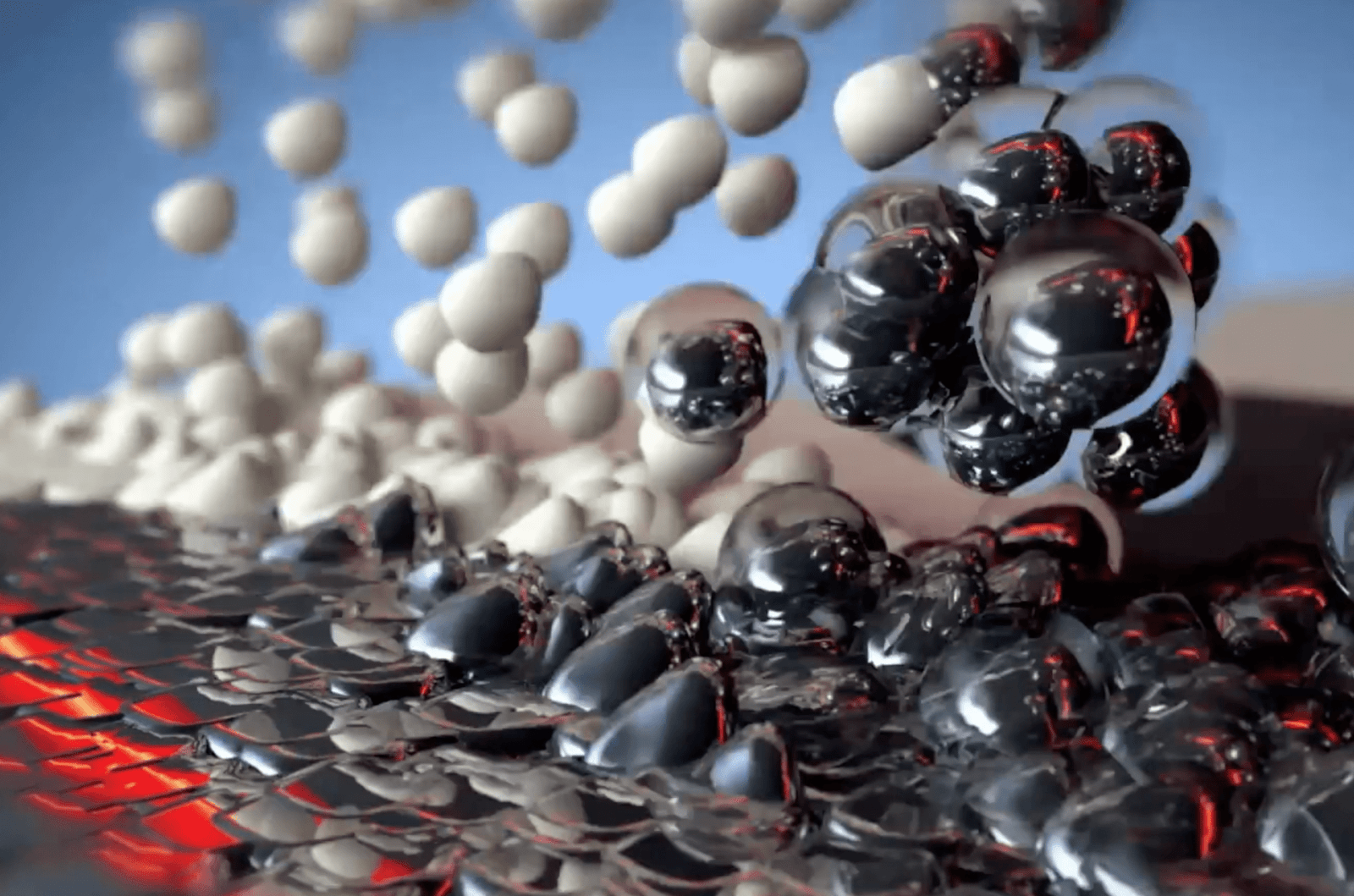

- TI6Al4V

- DM 625

- DM 247

- DM 4140

- DM 718

- DM H13

- 304L Stainless Steel

- 420 Stainless Steel

- 4340 Low-Alloy Steel

- 440C High Carbon Martensitic Stainless Steel

- 4605 Low-Alloy Steel

- Aluminum 6061

- Bronze

- Cobalt Chrome

- Copper

- DM HH Stainless Steel

- Gold

- H13 Tool Steel

- Hastelloy

- Haynes 230

- Iron-Chrome-Aluminum

- M2 Tool Steel

- Nickel Alloy Inconel 625

- Nickel Alloy Inconel 718

- Nickel-Free Austenitic Stainless Steel

- S7 Tool Steel

- Silver

- Titanium (Ti64)

- Tungsten

- Tungsten Carbide Cobalt

- Tungsten Heavy Alloy

- TZM Molybdenum

Azoth’s additive technology is a disruptive force in traditional manufacturing through its quick production lead times and TOMO® (Take One Make One). The TOMO process is designed to convert physical inventory to digital inventory eliminating supply chain disruptions, inventory obsolescence and saving its partners significant inventory costs and cash flow.

Azoth’s additive technology is a disruptive force in traditional manufacturing through its quick production lead times and TOMO® (Take One Make One). The TOMO process is designed to convert physical inventory to digital inventory eliminating supply chain disruptions, inventory obsolescence and saving its partners significant inventory costs and cash flow.

Our Industries

Our Industries

Our Industries

Our Industries